The Roar Solutions Statements

The Roar Solutions Statements

Blog Article

The Definitive Guide to Roar Solutions

Table of ContentsRoar Solutions for BeginnersGetting My Roar Solutions To WorkFascination About Roar SolutionsUnknown Facts About Roar Solutions

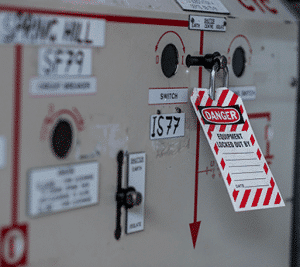

The devices register is a thorough data source of equipment records that consists of a minimum set of areas to recognize each product's place, technical criteria, Ex lover classification, age, and ecological data. This information is important for tracking and taking care of the devices effectively within unsafe locations. On the other hand, for regular or RBI sampling evaluations, the grade will be a combination of In-depth and Close examinations. The proportion of In-depth to Close assessments will certainly be figured out by the Equipment Risk, which is examined based upon ignition threat (the chance of a resource of ignition versus the possibility of a combustible atmosphere )and the unsafe area classification( Area 0, 1, or 2). This variant will also influence the resourcing requirements for job prep work. Once Great deals are specified, you can create tasting strategies based on the sample size of each Lot, which refers to the number of random devices products to be checked. To determine the required sample size, 2 aspects require to be evaluated: the dimension of the Whole lot and the group of assessment, which suggests the level of initiative that ought to be used( reduced, normal, or boosted )to the inspection of the Great deal. By integrating the group of examination with the Lot size, you can then establish the ideal being rejected requirements for an example, suggesting the allowable number of malfunctioning products discovered within that example. For even more information on this procedure, please describe the Energy Institute Guidelines. The IEC 60079 typical advises that the maximum period between examinations need to not go beyond three years. EEHA inspections will certainly additionally be carried out outside of RBI projects as part of arranged maintenance and tools overhauls or fixings. These assessments can be credited towards the RBI sample sizes within the influenced Great deals. EEHA assessments are conducted to identify mistakes in electric equipment. A weighted scoring system is necessary, as a solitary tool may have numerous mistakes, each with differing levels of ignition risk. If the mixed score of both inspections is less than twice the mistake rating, the Whole lot is regarded appropriate. If the Lot is still taken into consideration inappropriate, it has to go through a full examination or reason, which might activate more stringent evaluation methods. Accepted Lot: The sources of any faults are identified. If a common failing setting is discovered, added equipment may need evaluation and fixing. Faults are identified by seriousness( Security, Integrity, Housekeeping ), ensuring that urgent concerns are examined and dealt with promptly to alleviate any type of effect on security or operations. The EEHA database need to track and tape the lifecycle of mistakes in addition to the corrective actions taken. Carrying out a durable Risk-Based Evaluation( RBI )approach is essential for making certain compliance and safety and security in handling Electric Devices in Hazardous Locations( EEHA). Automated Fault Rating and Lifecycle Management: Easily take care of mistakes and track their lifecycle to enhance assessment precision. The introduction of this assistance for risk-based examination even more enhances Inspectivity's placement as a best-in-class remedy for governing conformity, as well as for any asset-centric evaluation use situation. If you have an interest in finding out extra, we welcome you to ask for a presentation and discover just how our service can change your EEHA administration processes.

With over one decade of consolidated Ex-spouse experience (IECEx/ATEX, EEHA), Saipex began to advertise the significance of competence of all employees involved in the Hazardous Location area in 2019. In 2021, our partnership with IndEx and Technology Skill International (TSI) noted a milestone in the Saipex roadway to proceed Ex lover improvement.

Some Known Details About Roar Solutions

In regards to eruptive risk, an unsafe area is an atmosphere in which an explosive ambience is present (or may be expected to be present) in quantities that need unique preventative measures for the construction, installation and use devices. In this post we discover the obstacles encountered in the workplace, the risk control procedures, and the called for expertises to function securely.

(https://leetcode.com/u/roarsolutions/)

It is a repercussion of contemporary life that we produce, keep or deal with a series of gases or liquids that are deemed flammable, and a variety of dirts that are deemed flammable. hazardous area course. These compounds can, in specific problems, develop explosive ambiences and these can have significant and terrible consequences. A lot of us recognize with the fire triangular eliminate any kind of among the 3 aspects and the fire can not occur, yet what does this mean in the context of harmful areas? When breaking this down into its most basic terms it is basically: a combination of a certain quantity of release or leakage of a particular material or material, blending with ambient oxygen, and the visibility of a resource of ignition.

This is after that verified via assessment and screening and is protected throughout the life of the installment by employing the right maintenance methods, supplemented by routine evaluation. When all these procedures are taken, they should likewise be recorded. The verification file includes details such as the harmful area category illustration, makers' paperwork, equipment certification, style illustrations and calculations, assessment records, and records of an individual's competency and continuing expert growth (CPD), such as via ECA's eCOMS software application.

Some Known Details About Roar Solutions

It is imperative that trainees comprehend and have an extensive expertise regarding what specifically comprises an unsafe area. The student should additionally recognize why training is necessary prior to attempting to handle job or specifying devices right into an unsafe location. These locations are also referred to as categorized areas and are specified as locations which have a high chance of a surge due to the feasible presence of combustible gases, vapors, cleans and so on.

Industries that consist of hazardous areas are currently requiring that electrical employees that are specifying or operating in these locations should have a dangerous area certification that deems them proficient. Jobs in these sectors are very gratifying so you need to be prepared. To meet this need for the industry, across the country acknowledged training in Certification IV in Harmful area Electrical and EEHA training on the development of experienced professionals.

The Of Roar Solutions

Technology Abilities Australia is a Registered Training Company giving you with the blog here most budget-friendly and quickest method obtaining your qualification - Roar Training Solutions. Our instructors are industry certified and have numerous years of procedure experience. Our training courses have actually helped numerous people from business supervisors to day-to-day employees in getting a strong hang on this not so difficult yet high danger training

The training also includes recognizing the dangerous areas, sources of explosion and the homes of hazardous products in addition to the duties and functions of all parties, laws, systems, requirements and technique codes linked to dangerous areas. We offer instrumentation and hazardous location options that are in compliance to most current AS/NZS and global industry criteria.

Report this page